White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

A leading technology company solved EM interference in battery test systems using fiber-optic CAN repeaters and a CAN bridge, ensuring reliable and precise data communication over long distances.

A powerful pair: Fiber-optic repeaters and a CAN bridge ensure reliable data communication in battery test systems.

In the rapidly evolving field of electromobility, precise and reliable battery tests are crucial in ensuring that battery systems deliver power reliably. A leading technology company specializing in battery test systems faced a challenge. Electromagnetic interference was hampering the communication between their test PC and their battery emulator. These interferences lead to constant error patterns (destroyed CAN frames) on the CAN line, which leads to an extension of the measurement time and inaccuracies during testing. This user report describes how they were able to overcome the challenge with a combination of CAN repeaters, fiber-optic cables as a bus medium, and CAN bridges. The result was high-performance, reliable data communication between all system nodes in the battery test system.

After production, battery modules are connected to battery emulators and test PCs to check their functionality under full load.

Every battery test system consists of several distinct components. The system’s brain is a test PC running the diagnostic and test applications that measure charging cycles, voltages, temperatures, and many other quality assurance parameters. The PC is connected to a so-called battery emulator, which realistically simulates battery charging and discharging processes and can produce dynamic load profiles. As a high-stability voltage source, it supports tests that speed up the characterization of electric drive components and improve their reliability. The emulator is directly connected to the battery under test. The company’s technical challenge manifested itself in destroyed CAN frames on the bus between the test PC and the battery emulator.

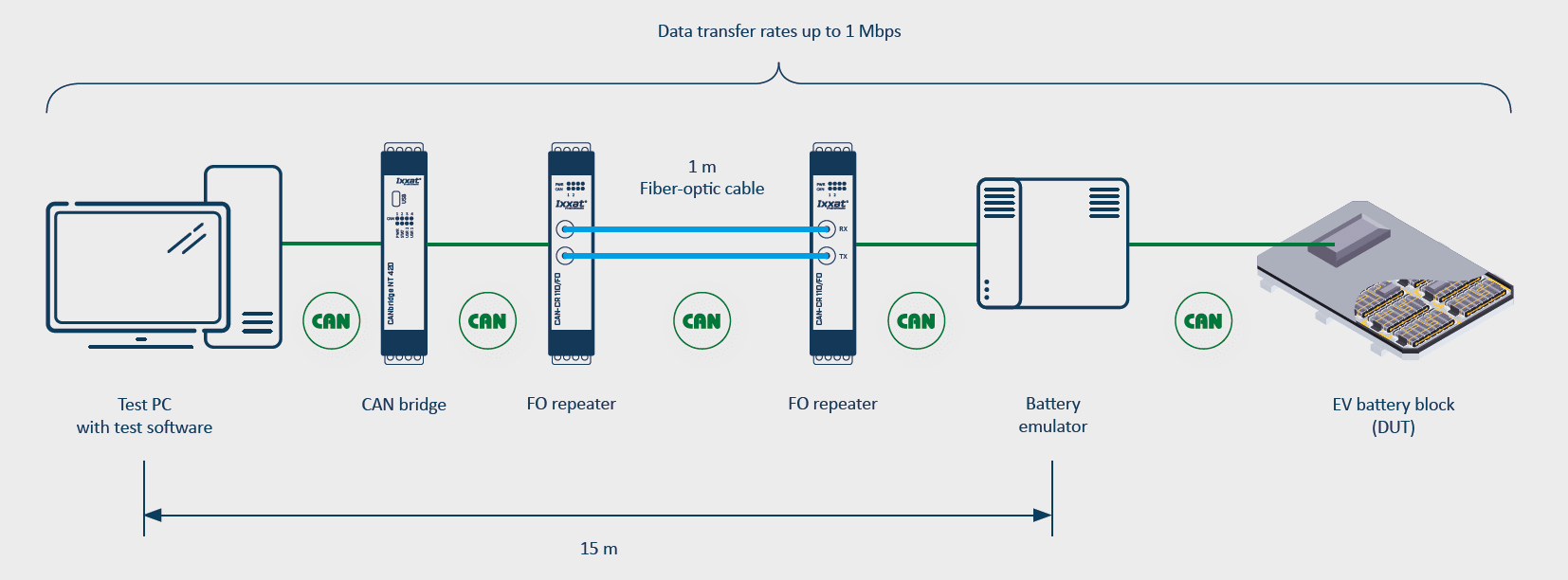

Since the test PC and the emulator are in different places, a CAN line over a distance of 15 meters is needed. The CAN line needs to transfer data at a rate of 1 Mbps. The destroyed CAN frames are triggered by EM interference with the battery emulator. The emulator works under high current loads during battery or electric motor tests, producing large amounts of stray radiation. The destroyed CAN frames on the fieldbus slow down the test processes and cause invalid results.

To overcome the electromagnetic interference, the company implemented a combination of two CAN repeaters and a CAN bridge. Using fiber-optic CAN repeaters avoids the interference caused by the electromagnetic radiation from the emulator and enables the signals to be transmitted reliably over long distances without loss of quality. The high data transfer rate and the need for two fiber-optic CAN repeaters caused the maximum bus length to be reached. In this situation, another component offered a solution. After the first transmission line, a CAN bridge doubles the maximum bus length and increases the network’s efficiency and flexibility.

In contrast to CAN repeaters, bridges work at the telegram level. The telegrams are received in full on a device, processed further and sent to one or more interfaces. The internal processing makes it possible, among other things, to connect networks with different speeds, to filter and duplicate telegrams, or to derive information from telegrams. Repeaters, on the other hand, work at the bit level, i.e. on a purely electrical basis, and thus forward telegrams unchanged.

The CAN-CR210/FO repeater is specially designed for use in environments with strong electromagnetic emissions. It converts CAN signals from a copper cable so they can be transmitted through a fiber-optic cable and vice versa. The non-conductive fiber-optic cable has the advantage of virtually infinite galvanic isolation and is also impervious to the electromagnetic interference that occurs with ordinary copper cables. The CAN repeater is especially effective at minimizing signal losses over long distances, offering a robust solution for complex industrial test systems. In the situation described here, the CANbridge NT 200 plays a key role in extending the bus length. It can double the maximum bus length, allowing greater flexibility in the placement of test equipment and PCs, even over longer distances. It also features advanced functionality like data filtering and routing, which optimize network performance and simplify administration.

Combining the fiber-optic CAN repeaters and CAN bridge proved to be an effective solution to prevent interference with data communication during battery tests. By using these technologies, the company was able to reduce the number of test repetitions and thus significantly reduce costs.

Country: USA

Solution: Network gateways

Industries: Battery test systems

Products: Ixxat CAN-CR210/FO and CANbridge NT 200

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.