White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Automated guided vehicles (AGVs) in automotive assembly lines achieve improved performance and reliability using Siemens SIMATIC S7-1200 controllers and Ixxat CM CANopen extensions.

CANopen as a backbone network

Automated guided vehicles (AGVs) have become essential to meeting the flexibility and efficiency requirements of modern automotive assembly lines. They are used in the automated production lines for engines, front and rear axles, transmissions and chassis, for delivering materials to lines for processes such as stamping and welding, and for partial or complete assembly. A Chinese supplier of AGVs uses a combination of Siemens SIMATIC S7-1200 controllers and the compatible CM CANopen PLC extension to control its vehicles. Integrating this reliable pair in an automotive assembly line in Suzhou, China, led to considerable improvements in the performance and reliability of the AMRs used there.

Automotive assembly lines need sturdy and flexible transport systems that can deal with long distances efficiently. The customer needed a solution combining safety, reliability, expandability. cost-effectiveness, and short time to market. In the worst case, production stoppages can cause millions in losses, so the choice of vehicle controller was particularly important as it controls the behavior of an AGV’s individual hardware components.

The controller is the centerpiece of an AGV, and there are three basic options for it: a PLC, an integrated industrial PC, or an embedded system. As a rule, an industrial PC is relatively expensive and the development process for embedded systems is highly demanding.

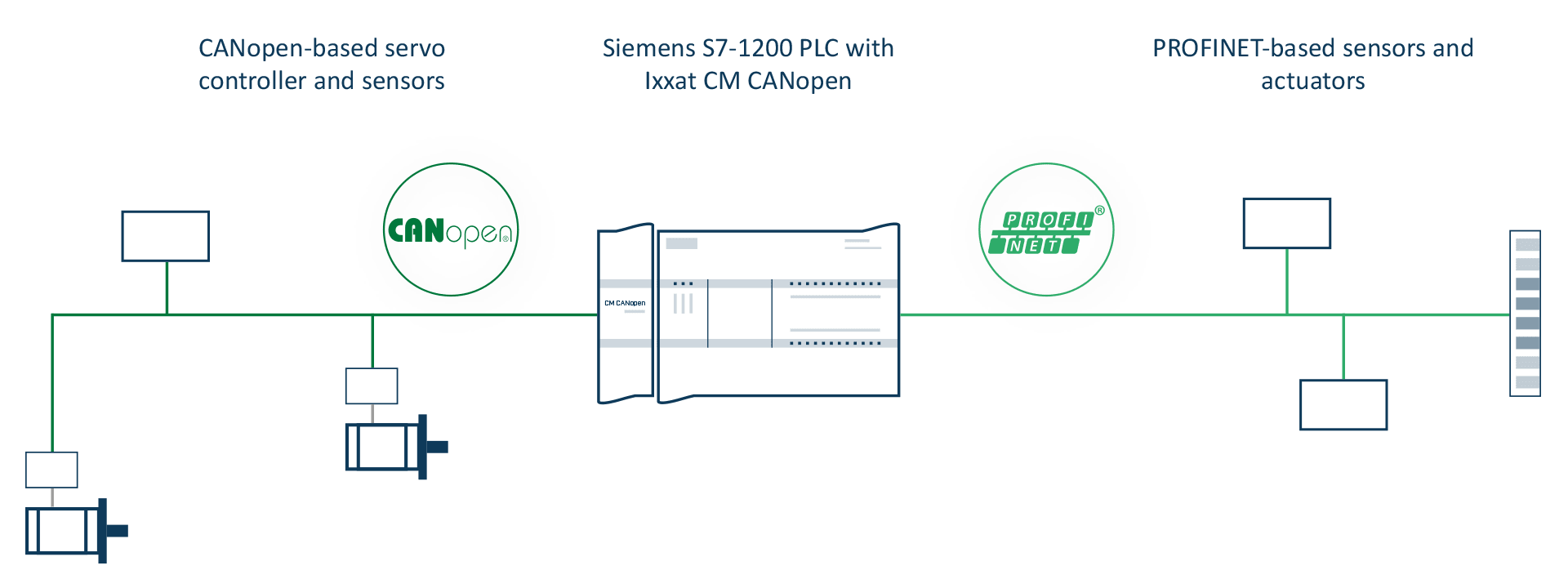

After an in-depth evaluation, the customer decided on a combination of the S7-1200 PLC from Siemens and the Ixxat CM CANopen communications module from HMS Networks. Not only did this solution meet their safety and reliability requirements, it was also cost-effective and could be implemented quickly. The compact components and the expandable and flexible design met the customer’s requirements as well.

The CANopen protocol’s inexpensive implementation is a key advantage that makes it a standard for many drive manufacturers, and CAN technology is already an established standard in battery engineering. But the customer also chose the protocol because its mature, transparent and easily understood design simplifies driver development considerably. These characteristics make it especially useful for industrial applications in which simple implementation and consistent performance are crucial. Another feature of the CANopen protocol is its high reliability, which makes it ideal for critical automation tasks. CANopen’s user-friendliness is a further argument in its favor as it enables ease of use. Its combination of reliability, user-friendliness and cost-effectiveness has helped CANopen establish itself as a sound choice for industrial data communication.

As the component that enables control of all movements, the CM CANopen extension module from HMS plays a key role in the smooth operation of autonomously navigating AGVs. The customer was able to integrate the module directly in the PLC by installing it in the S7-1200 PLC rack, simplifying both installation and operation. An HSP file was also provided; it enabled simple configuration of the device via direct import into the TIA portal.

The module supports both CANopen master and slave functionality and transparent communication via CAN 2.0A for flexibility and versatility. Up to 16 CANopen slaves can be connected to a CANopen master, and the S7-1200 PLC can accommodate up to 3 CM CANopen modules, providing considerable scope for expansion. CM CANopen Configuration Studio is an intuitive and user-friendly program for quick and easy configuration, making it easier to use the module in a variety of applications. These features make the CM CANopen module the ideal choice for complex automation tasks.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.