White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Read how Furness Controls used the Anybus Communicator to quickly connect to industrial networks and the advantages of transitioning to the Anybus CompactCom.

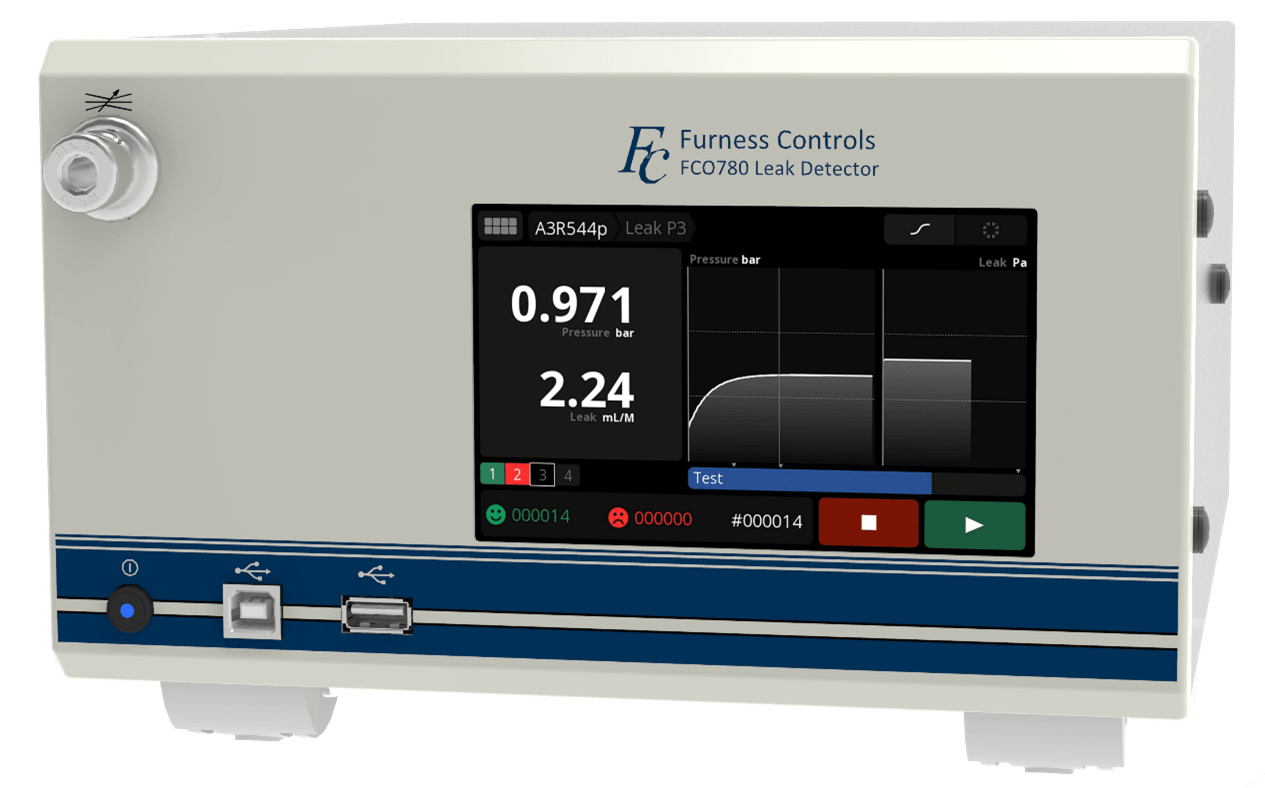

Furness Controls has been a leading manufacturer in ultra-low range differential pressure measurement, leak detection, and flow measurement for over 50 years. Based in the UK, the company specializes in producing micromanometers, pressure decay leak detectors, and flow measurement devices for industries such as automotive, aerospace, medical, and food processing.

Furness Controls has seen a significant evolution in how leak detectors are used in modern manufacturing. Previously, leak detectors operated independently, measuring pressure and providing simple pass or fail results through visual indicators like red or green lamps to operators. However, as manufacturing processes have become more automated, there’s now a growing demand to integrate leak detectors with manufacturers’ PLCs (Programmable Logic Controllers). Companies want their PLCs to directly manage the leak detectors, perform tests, and collect data in real-time, without manual intervention.

“We got accepted as the global supplier of leak detectors to Faurecia, which was fantastic for us,” recalls Ian Clarke. “However, one of their requirements was that our leak detector, which uses an RS-232 interface, had to connect to their PROFIBUS network—something we had no idea how to implement.

Fortunately, an integrator connected to our German sales team recommended the Anybus Communicator, having used it successfully in another project. We took their advice, used an Anybus Communicator, and it worked well. That was around ten years ago, and it was a start of a good partnership with HMS.”

Since then, Furness Controls has received more requests from companies in various locations to connect their leak detectors to PROFINET and EtherNet/IP networks. “As more requests came in, we decided to integrate the Anybus Communicator directly into our leak detection units. Our units aren’t big, but we managed to squeeze the Anybus Communicator in, so we could now provide units with an EtherNet/IP or PROFINET interface.”

Furness Controls uses a block transfer serial protocol developed in-house, which initially raised concerns about compatibility with the Communicator. However, Ian expressed relief at the seamless integration, stating, “We were slightly worried that the communicator wouldn’t actually understand that protocol, but luckily it all naturally sat into it. It’s got the same checksum functionality built in. It was all really surprisingly easy.”

As the design of the Anybus Communicators became larger and the leak detector units got smaller, it became impossible to include the Communicator inside the leak detection units.

However, Furness Controls was pleased with the quality and reliability of the Anybus Communicators over the years, prompting them to implement the Anybus CompactCom, a communication interface designed for embedding inside industrial devices and machines.

“The space issues are what prompted us to look at the Anybus CompactCom. We wanted to see if it could offer the same functionality,” Ian recalls. After testing, they confirmed that it could. “We can provide the functionality we’ve always supplied, but even with the addition of electronics and microcontrollers, the Anybus CompactCom takes up about a quarter of the physical space compared to the old Anybus Communicator. And it gives us one neat plug-in module that we can put into our unit.”

Transitioning to the Anybus CompactCom has brought several key benefits. The reduced size allows Furness Controls to integrate additional functionality into their units. For instance, customers sometimes request a sequence box along with network connectivity, but previously there wasn’t enough space for both inside the unit.

“It was always tough to tell customers that one of those would have to be external, as they preferred a complete, all-in-one solution.” The smaller footprint also makes it easier to keep CompactCom units in stock. Additionally, they can now use the leak detector’s web interface to update the CompactCom remotely. The lower unit cost is another advantage. “Even with the extra design work and adding electronics, it still works out a lot cheaper. The design work is also a one-off cost, which is great as we might add connectivity to other networks like EtherCAT in the future.”

While the Anybus CompactCom offers several advantages over the Anybus Communicator, Ian has no regrets about beginning with the standalone Communicator. “The Communicator is easier to get up and running, and it helped us to quickly launch a product that could connect to the required networks.” This initial experience also helped them understand Anybus products, making the transition to the CompactCom smoother and more efficient. “From start to finish, it took about six months to implement the Anybus CompactCom.”

Company: Furness Controls

Country: United Kingdom

Year: 2024

Solution: Network connectivity

Products: Anybus Communicators and Anybus CompactCom

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.