White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

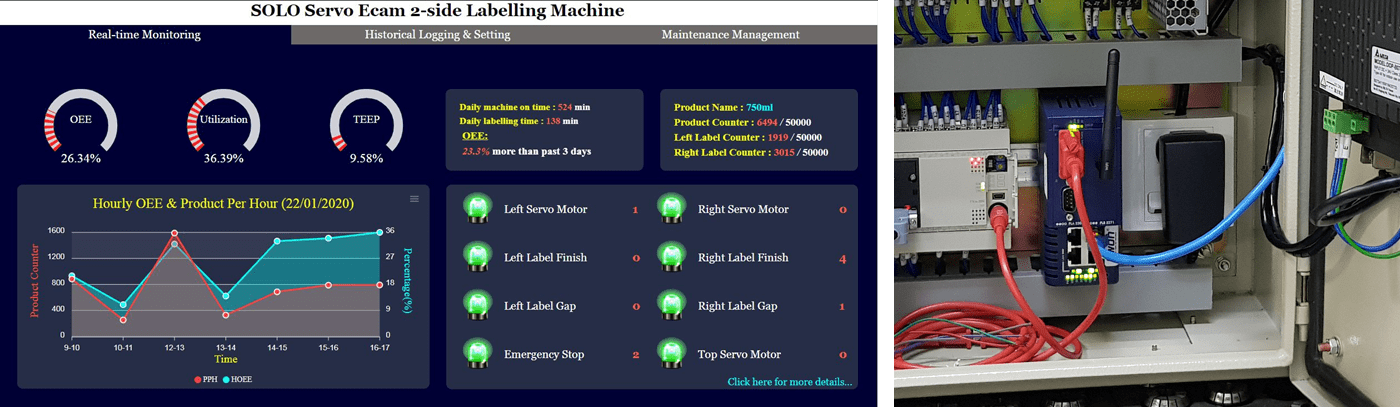

Solo Labeller Technology implemented proactive remote monitoring using the Ewon Flexy 205 and Talk2m. This IIoT system provides real-time monitoring, hourly performance trends, and historical data. It also enables automatic email notifications for critical situations and predictive maintenance.

Solo Labeller Technology Sdn Bhd is a leading manufacturer in Malaysia and a complete solution provider for labeling machines & processes. Since 1993, they have sold and serviced over 700 machines in more than ten countries. They have recently expanded their business to include 3D printers and industrial IoT (IIoT) systems. Simplicity, reliability and precision are their business motto.

As a labeling machine manufacturer and solution provider, Solo Labeller had a keen interest in the many applications of Industry 4.0, such as robotic arm automation and IIoT applications. They were convinced that by researching, developing and implementing the latest technologies in their products, they could increase their competence and brand image in the market.

We plan to include more and more information about our machines in our IIoT system. The next step will be to optimize our machine data acquisition and visualization process.

Solo Cheong, Director, Solo Labeller Technology Sdn Bhd

The implementation of IIoT in their labeling machines was a real breakthrough. For this purpose, they decided to use an HMS’ IIoT gateway recognized for its reliability, namely the Ewon Flexy 205. It allows them to simply and securely connect their labeling machines to the Internet and to the Ewon Talk2m remote connectivity cloud service. Thanks to this, it becomes possible to establish in just a couple clicks a secure remote connection to monitor the status of the equipment through modern HTML dashboards. This way, they can assure their customers that they are always aware of what is happening in their labeling process.

The HTML dashboards are made possible thanks to Ewon Flexy’s embedded viewON: a graphical environment used to design animated HMI pages. It transforms the Ewon Flexy into a powerful remote dashboard containing complete synoptics with various objects & animations. Several metrics are displayed on Solo Labeller’s dashboards, such as utilization, OEE (Overall Equipment Effectiveness), and TEEP (Total Effective Equipment Performance), to indicate the status of their machine’s daily performance. A trend graph of hourly OEE and product per hour also reflect the performance of the machine on an hourly basis. By viewing these dashboards, their clients can also know the current running product, the number of completed products, the triggered alarms, and the total number of triggered alarms.

Solo Labeller uses Ewon Flexy to easily generate HTML dashboards. These include important KPIs useful for proactive remote monitoring.

Using the alarm logging system provided by the Ewon Flexy and the Talk2m cloud service, Solo Labeller can accurately record the time of each alarm triggered for archival purposes. On the other hand, the historical data logging shows the performance of their machine over the last seven days. This record can be scaled down to an hourly basis, so the customer can see if there is a sudden drop in production rate and corrective action can be taken.

To make things even better, when there is a continuous drop in the hourly production rate or a prolonged alarm scenario, the system automatically sends an email to inform the machine supervisor that something has happened on the labeling machine.

If necessary, Solo Labeller’s service engineers can provide immediate remote support to their customer by establishing a secure VPN connection through Talk2m.

Finally, this system can continuously record the runtime of all wear & tear parts and motors of the labeling machine. When a given part is almost out of service, Solo Labeller sends their technician to inspect and replace it. In this way, they have achieved predictive maintenance that has significantly reduced the downtime of their labeling machines.

With the implementation of the Ewon Flexy and thus of an IIoT system in their labeling machines, they have achieved the following:

In conclusion, Solo Labeller Technology Sdn Bhd, with a focus on continuous product improvement, has taken full advantage of IIoT thanks to the Ewon Flexy and Talk2m.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.