White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

The Ixxat CM CANopen simplifies automation upgrades in logistics centers by connecting new PROFINET PLC systems with old CANopen-based conveyor belts.

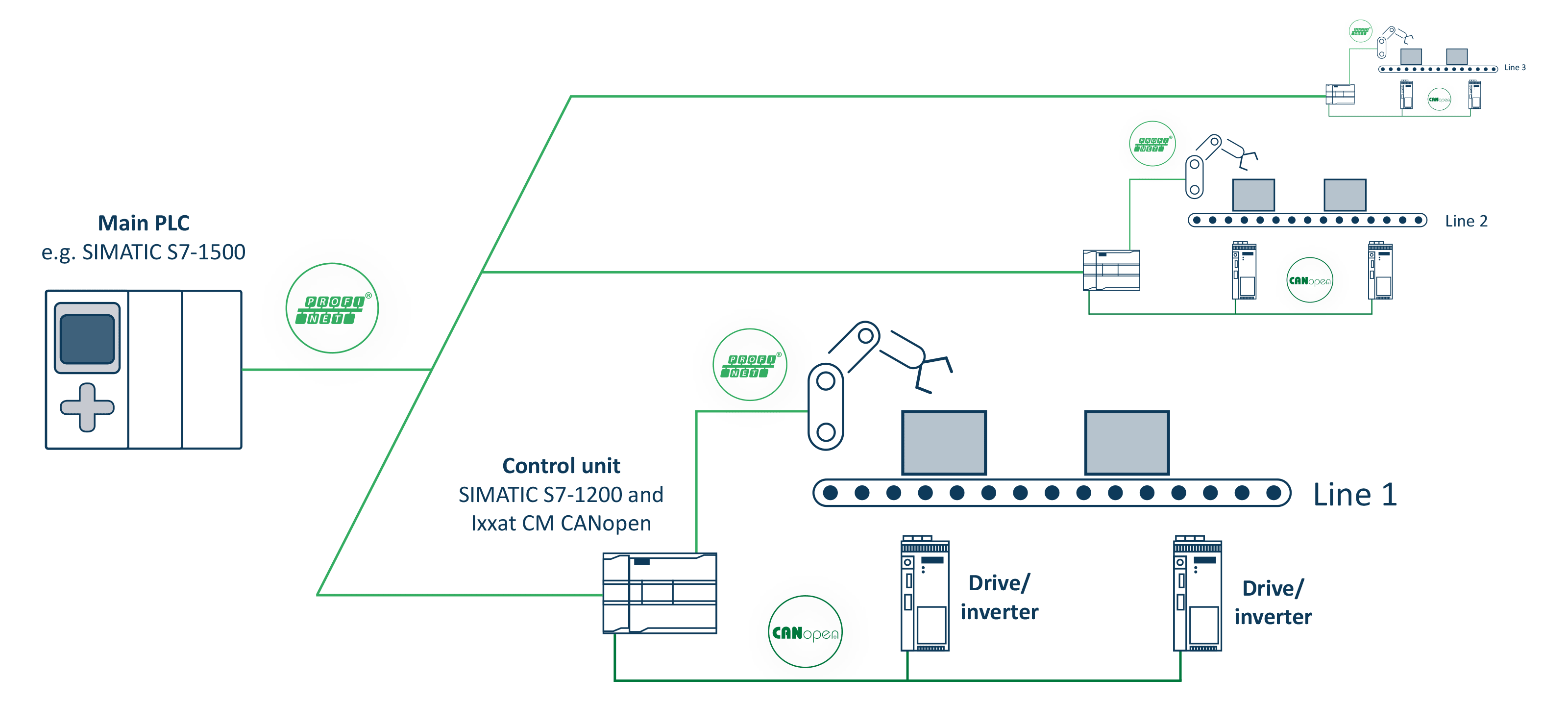

Build new or upgrade? Greenfield or brownfield? These questions often arise in connection with complex intralogistics facilities with numerous aging conveyor belts, input and output zones, and packaging and handling units. To meet modern requirements for fully automated warehousing and conveyor equipment while also implementing the latest technology economically, retrofitting experts recommend the brownfield approach. A major German logistics integrator applied such a retrofit approach for one of its customers and had to deal with a number of technical challenges. The task: integrating new and fully automated handling systems in the existing facility. This meant the PROFINET-based communication at the control level needed to be linked with the CANopen communication at the field level.

The new PROFINET communications protocol for the handling systems had to be linked with the existing CANopen communication used for the electric conveyor drive motors.

With 5 packaging stations, 10 robotic handling units and a conveyor system extending over almost 400 meters, a new network topology was called for to accommodate everything from the main control unit, a Siemens SIMATIC S7-1500, to every drive at the field level. A compact and economical solution had to be found, and that ruled out an expensive replacement of the conveyor drives from the outset.

The integrator turned to HMS Networks with its communications challenge and found what it needed. The Ixxat CM CANopen master/slave module met all of the technical requirements. For each packaging station, a Siemens SIMATIC S7-1200 control unit was installed with an additional CM CANopen communications module. Up to 16 conveyor drives could be connected to each module, with the signal converted to a PROFINET signal directly in the PLC. Acting as a bridge, the compact and economical expansion module for all S7-1200 controllers simplifies the communication and data transfer between the actuators, the distributed subcontrollers, and the central control system. Thanks to their compactness (30 × 100 × 72 mm), up to three modules can be easily plugged into a single S7-1200 controller and mounted on a top-hat rail.

The Ixxat CM CANopen master/slave module supports transparent CAN 2.0A for the implementation of customer-specific protocols and increases the efficiency of PLC programming with pre-programmed function blocks that are available in the TIA Portal. The module is listed as a component in the Siemens automation tool TIA Portal for easy integration in the Siemens universe without additional programming effort. The included CANopen Configuration Studio software makes it easy to select application-specific function blocks and configure them right in the module via a USB connection. In addition, the CM CANopen interface has integrated LEDs that provide users with detailed diagnostic information about network and I/O status for simplified troubleshooting.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.