Machine builders and users use industrial remote access to connect to, monitor and update their machines from anywhere at any time. The next, slightly more sophisticated step is to collect data from the machines for use in third-party applications and leverage it to improve overall equipment efficiency (OEE), minimize downtime and manage predictive maintenance. Industry 4.0 is here at the crossroads between IT (Information Technology) and OT (Operation Technology). Both are interdependent while having different approaches.

Industry 4.0 is the digital transformation of manufacturing and related sectors, often interchangeably referred to as the "fourth industrial revolution." It refers to a new phase in the management and control of the industrial value chain.

Industry 4.0 is often used as an umbrella term for various domains such as AI (Artificial Intelligence), Big Data, Machine Learning, IIoT and many others in the industrial world.

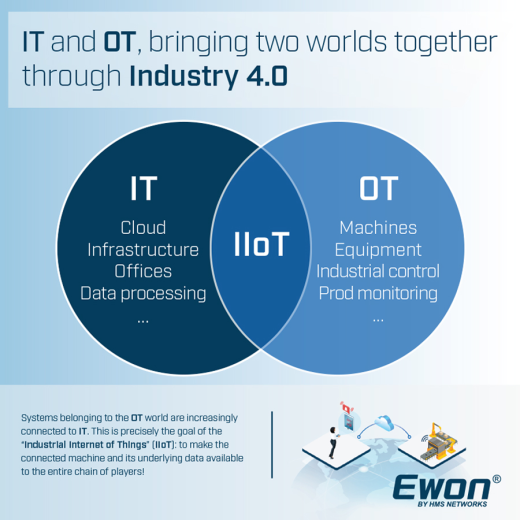

With the emergence of Industry 4.0, the convergences between IT (information technology) and OT (operational technology; used to control industrial equipment), previously separated, are multiplying. Whereas they were once isolated in physically secure areas, systems belonging to the OT world are increasingly connected to IT.

This is precisely the goal of the "Industrial Internet of Things" (IIoT): to make the connected machine and its underlying data available to the entire chain of players, from machine builders to end users and suppliers.

By analyzing data, machine builders and users facilitate maintenance, improve knowledge, interconnect processes and ultimately create added value by improving productivity.

While IT and OT are increasingly working together in this Industry 4.0 era, it is necessary to understand their differences in terms of security

Industrial process failures typically impact the physical world. It can, for example, adversely affect human health, as well as the environment (e.g. when hazardous material leaks occur). The growing convergence between IT and OT creates new security challenges for any Industry 4.0 stakeholder. On one hand, IT can be seen as the Far West, where black hats, white hats and grey hats have always clashed.

On the other hand, OT has long been - due to its lack of connection to the outside world - like an ancient fortress, mainly protected by physical measures preventing access to industrial equipment. The challenge brought by Industry 4.0 is that IT vulnerabilities might now impact the OT world. It is therefore crucial to maintain the highest level of IT security, in order to avoid any impact on the industrial world.

As IT vulnerabilities now have an impact on the industrial world, it is essential to ensure that they are properly addressed in an industrial context. That’s precisely why Ewon solutions are ISO 27001 certified. This comprehensive, well established standard applies to both IT and OT and across domains (e. g. offices as well as a factories, banks as well as a power plants) and is thus perfectly suited for Industry 4.0. It is the most widely used security standard in the world, published by the International Organization for Standardization (ISO), an internationally recognized organization.

With its ISO 27001 certification, Ewon by HMS Networks has implemented comprehensive security programs that protect information.

Ewon is audited on every of the 114 controls listed in Annex A of ISO 27001. This provides the level of security that industrial companies are entitled to expect. Ewon pays particular attention to the implementation and compliance of all these measures from devices to the cloud as well as in its own infrastructure, ensuring that machines and data are well protected.

Such certification is not easy to achieve, but it is a guarantee to provide secure solutions to machine builders and users, as these measures help protect the information used in IACS (Industrial Automation and Control Systems) and ensure that processes are effective in implementing security practices.