White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Comprehensive network health analysis by the HMS support team and subsequent application of the appropriate CAN topology solutions enabled robust and reliable CAN BMS communication for the customer in their grid-scale BESS deployments.

The customer is designing and deploying modular, scalable BESS which utilize high bitrate CAN bus in the BMS network architecture. Controller Area Network (CAN), originally used in the automotive sector, is known for its robustness. However, specific requirements must be met to maintain reliability and overall communication stability. These include specific demands for the network length and CAN topology as well as the cabling and terminations.

During early-stage commissioning of a multi-MW project, site technicians identified battery rack communications issues. Initial attempts to identify the root cause were unsuccessful, whereupon the customer contacted HMS to request assistance troubleshooting and resolving the issue and achieving communications stability in their battery/BMS network.

HMS leveraged digital tools to overcome time zones and provide thorough, remote troubleshooting support to a job-site halfway around the globe. Specific CAN bus analysis tools were utilized including Ixxat CANcheck and USB-to-CAN V2 combined with canAnalyser software interface.

For the error analysis, the customer carried out signal measurements on the bus and checked the wiring. Working jointly with the customer, systemic physical-layer problems were identified early. By analyzing the CAN waveforms, it was shown that the network instability was due to excessive capacitive load combined with signal reflections. Common contributors to such symptoms are (a) use of non-conformant cabling, (b) cabling length being exceeded, (c) lack of sufficient shielding/grounding.

Unfortunately, system re-wiring and cable replacement was not possible due to project requirements and physical limitations. A different approach was needed!

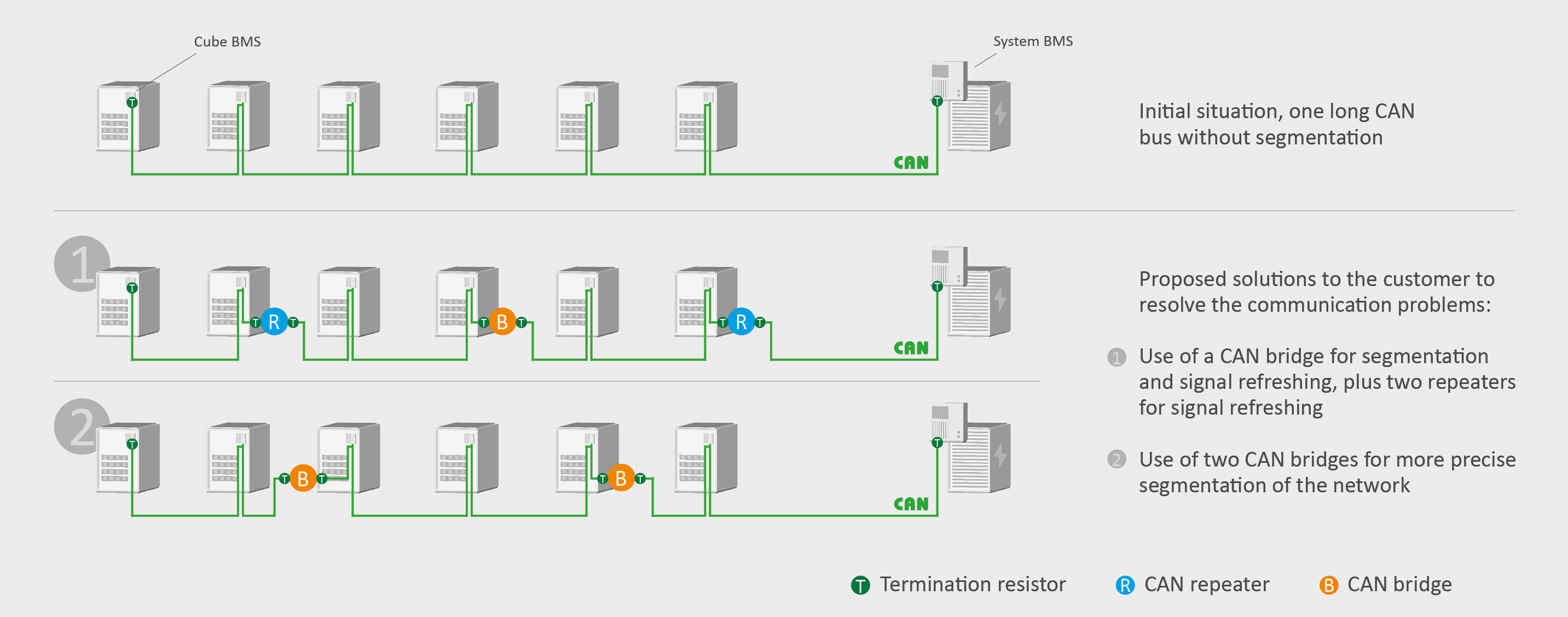

The total physical cabling length of this system was roughly 115 meters. Whereas a 500 kbit CAN network typically can achieve lengths of 100-110 m, the underlying issues on this system limited the length even more, before active error frames appeared. The HMS team suggested segmenting (sub-dividing) the network accordingly using the appropriate CAN topology components to improve the signal quality.

The intuitive choice – implementing CAN repeaters to “extend” the network – was not applicable for this system! Although CAN repeaters do provide bit-wise refreshing of signal levels, their signal propagation delay time effectively only adds length to a line topology network.

Instead, the larger CAN network was intelligently divided into multiple, shorter segments utilizing 2-channel CAN bridges, which offer message-wise “repeating” across all channels. This allows each sub-segment to maintain the intended baud rate along with the rest of the overall larger network. In addition, electrical disturbances are also not transmitted across the CAN bridge, which further improves the overall signal quality on all segments.

Through close collaboration with the customer, HMS was able to effectively analyze and troubleshoot the existing system remotely and recommend multiple paths towards a resolution. HMS’ experience in these situations combined with an extensive toolbox of diagnostic tools and CAN topology components lead to a successful resolution for the customer and a successful deployment of another large-scale Battery Energy Storage System.

Country: USA

Solution: Ixxat CAN topology

Industries: Battery Energy Storage Systems (BESS)

Products: Ixxat CANbridge NT and CAN-CR 300 repeater

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.