White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

By using a Ewon remote data solution, a manufacturer of high speed food tray sealing machines is now able to offer its customers a range of added value options including real time visualization, production management and fault diagnosis tools, which minimize costly downtime.

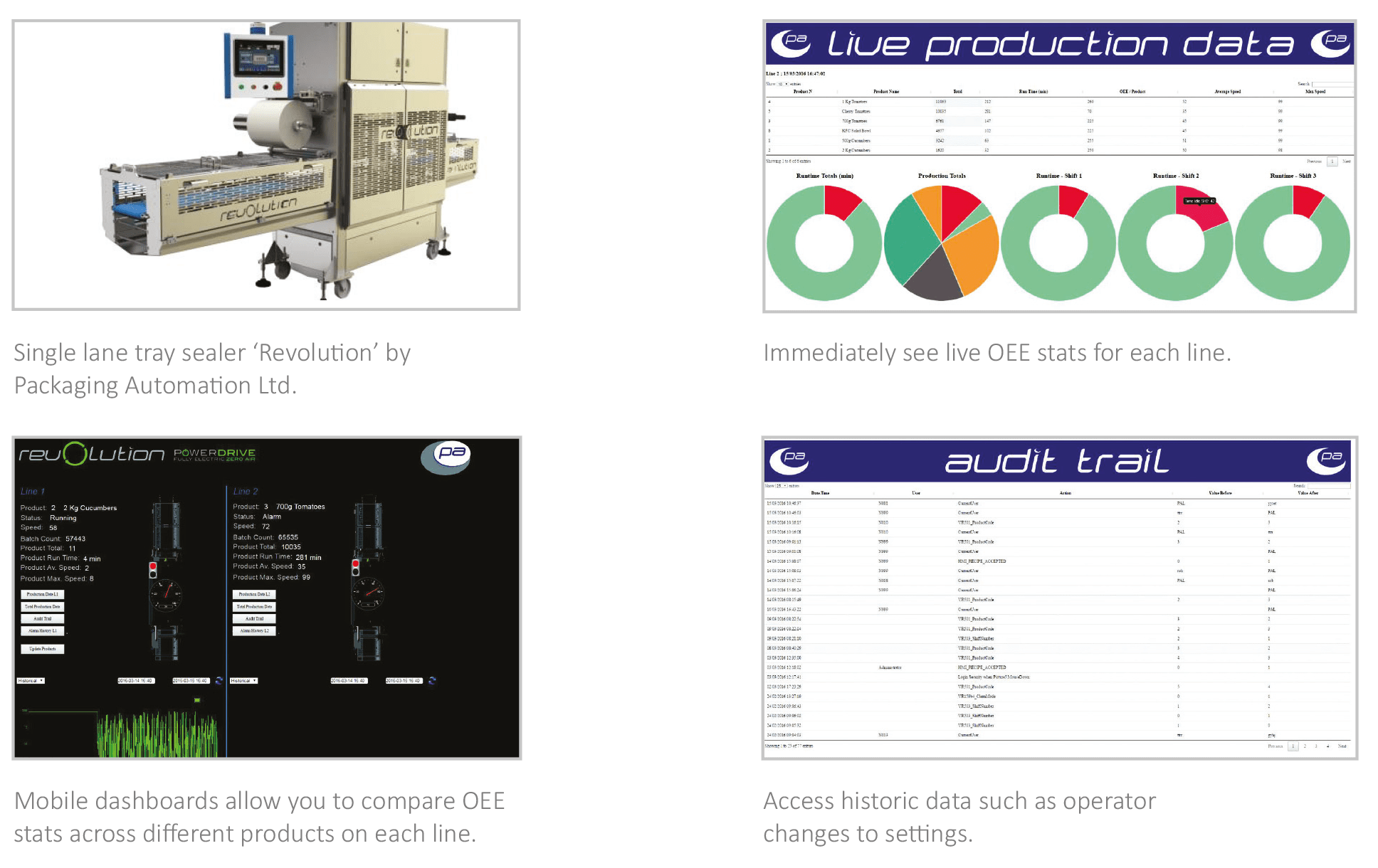

Based in Knutsford, Cheshire, Packaging Automation Ltd (PA) is a leading manufacturer of tray sealing and pot filling machinery, which are used in a wide range of applications in the food industry, including fresh produce, soft fruit packing, fish, seafood, meat, ready meals and sandwiches, as well as pot filling for puddings and sauces. Full packing lines can be specified and installed to include tray denesting, conveyoring, tray filling and film sealing.

Tray sealing machines are capable of sealing from 12 to 200 packs per minute. These machines are fitted with Ewon Flexy gateways, which enable remote diagnostics and real time visualization of live production data on the machines. As Rui C., Senior R&D Engineer at Packaging Automation Ltd states: “The Ewon Flexy gateway and Talk2m solution provide us with remote connectivity into the heart of the customer’s machine via the Internet. This enables our engineers to remotely access and diagnose faults, regardless of the machine’s location, so that we can get to the root cause of stoppages quicker and help our customers maintain higher levels of production and improved OEE [overall equipment efficiency]. These features are critical to our 24/7 customer support service.”

It very quickly became apparent that Ewon could provide exactly what our customers wanted in terms of real time production data.

Rui C., Senior R&D Engineer, PA Ltd

He continues: “In addition, we can also offer customers a live, web-based view of their machine and its current operating state [stopped/running], as well as live production statistics including output, current running speed and historic details of stoppages and changes to machine parameters. We’ve developed mobile dashboards that allow our customers to compare OEE statistics across different products on each line, which helps them to identify trends and performance variations by shift and line. Inefficiencies or idle time can be spotted quickly in order to prioritize improvement activities.”

In 2013, PA commissioned Lancaster University to conduct some market research on its customers. This involved asking a sample of PA’s customers what kind of data they would find useful to visualize on their tray sealing machines. The feedback was that they wanted to see live, real time production data in the form of KPIs, OEE, machine speeds, waste, efficiencies, audit trails, alarms, etc. As Rui C. comments: “Shortly after the research was concluded, I attended the Ewon FlexThink Conference in Belgium, where the Ewon Flexy was launched. Whilst there, it very quickly became apparent that the Ewon solution could provide exactly what our customers wanted in terms of real time production data. I also liked the fact that the solution was flexible, affordable and easy to integrate for both our small and large food producing customers.”

After the FlexThink conference, Rui contacted Ewon’s UK agent M.A.C. Solutions, who advised and guided Rui on how to integrate the Ewon Flexy with the tray sealing machines. “I’ve had a very good working relationship with M.A.C. Solutions over the last two or three years. The Ewon Flexy is a very flexible solution that allowed me to develop a range of added-value options on our high speed tray sealing machines over the space of about four months.”

“Ewon is a low cost solution that is easy to use, easy to deploy and easy to scale up. There is no dependency on an Internet connection, as the system still works locally if the customer only wants to use the system internally. For those customers who do use it over the Internet, web access is totally secure. Customers who use our production management [Data Connect] software absolutely love it and want more of it. We are therefore already developing new features and add-ons to satisfy these needs,” concludes Rui.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.