White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Efficient communication and synchronization in end-of-line battery system testing: The combination of CANnector as a DoIP gateway and CANeasy software reduces flash times by 20%, enhancing competitiveness.

DoIP gateway for classic bus systems:

The precise coordination of cycle times, flash synchronization, and data transmission speeds play a crucial role in the field of end-of-line-testing of battery systems. The ability to efficiently flash battery control units (ECUs) in the ongoing production process is critical for complying with cycle time specifications. A leading Asian expert in automation systems in the field of battery production and tests relies on the CANnector series from Ixxat, which can be used as a DoIP gateway, in combination with the analysis and test software CANeasy for the communication between the battery control unit and the diagnostic software. It is a solution that ensures competitive flash cycles.

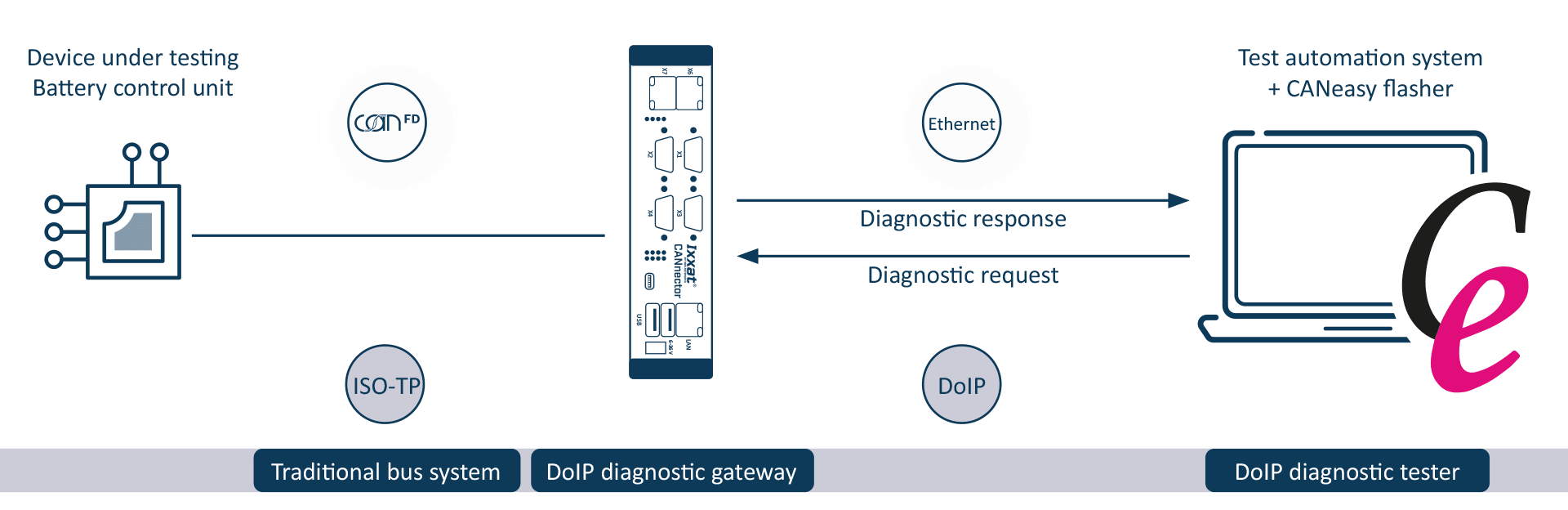

The customer, a system integrator from China, faced the challenge of complying with specified cycle times for the flash process of control devices. While the solution used to date technically worked flawlessly, it was not ideal to use the CAN FD bandwidth. The individual CAN packets were already prepared in the PC software, which led to longer latency times in transmission. By using DoIP as a diagnostic access via the CANnector, the splitting into CAN FD segments now takes place at the latest possible time, thereby reducing the latency times to a minimum. A faster solution was needed, since the potential savings when flashing per unit is enormous due to the short cycle times of EV batteries. Control units are typically flashed per CAN or CAN FD and usually do not have their own Ethernet interface. The test software used, CANeasy, i.e., the diagnostic tester, already supports DoIP (Diagnostics over IP), a standardized TCP/IP-based transport protocol for UDS (Unified Diagnostic Services), which allows for a high data transmission.

Therefore, the aim was to establish efficient communication between the traditional CAN-based bus system (control unit) and the Ethernet-based DoIP protocol (diagnostic tester CANeasy)—via DoIP gateway.

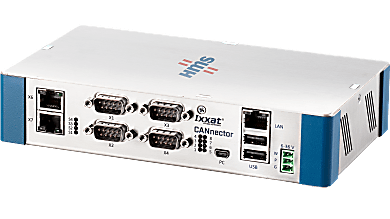

In order to reduce the duration of the flash cycles, the supported network transport protocol DoIP (Diagnostics over IP, ISO 13400-2:2019) was therefore relied on in the CANnector as well. The CANnector, which can be used as a DoIP gateway, is configured here as a network component in such a way that, in addition to DoIP, it also supports the transport protocol ISO-TP for CAN-based bus systems. This ensures that the UDS requests sent via DoIP can be forwarded directly to CAN/CAN FD. CANnector and other gateways from the automotive product family operate in standalone mode. This means that a configuration is created beforehand, which is permanently saved on the device. The HMS engineering software ACT (Advanced Configuration Tool) allows for simple configuration here and the connection with the diagnostic software CANeasy. Moreover, message catalogs, such as ARXML files, can easily be imported to ACT and the transport layout connections created there can be used as the basis for creating the configuration. The diagnostic process starts with a request from the tester, which contains the diagnostic service and the logical address of the control unit to be flashed. The gateway packs this packet in a CAN/CAN FD message and sends it. After receiving the response from the control unit, the CANnector working as a gateway send this back to the tester (CANeasy), which allows for quick and reliable communication.

The heart of the solution is the CANnector series, which can be used as a diagnostic gateway. In addition to DoIP, the CANnector series also supports the ISO-TP protocol and other functions, such as residual bus simulation, logging, and EtherCAT as an all-in-one platform. It works together seamlessly with the test software CANeasy, which enables a simple configuration and the importing of ODX and PDX flash containers. This combination of powerful hardware and software significantly reduced the flash times by 20 percent compared to the solution previously used. This meant that not only could the cycle time specifications be met, but the competitiveness on the market was also ensured.

Country: Germany

Solution: CAN connectivity

Industries: Warehouse and distribution

Products: Ixxat CANnector

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.