White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Protocol conversion gateways, like Anybus Communicator, integrate diverse equipment, enhancing system reliability. Our customer's quay crane monitoring system has successfully used Anybus gateways, improving efficiency and gaining industry recognition

This is a real case study. However, the client has chosen not to disclose their company information publicly.

Port terminals and port machinery are critical links in national infrastructure and economic activities. They not only serve as bridges in international trade but also as important nodes in domestic logistics and supply chain management. This equipment, including container cranes, loading and unloading bridges, automated stacking machines, etc., are the core of efficient port operation. However, due to the high intensity and variable operating environments in which these machines typically operate, such as extreme weather, salt spray corrosion, and continuous physical wear and tear, they are particularly prone to performance degradation and failure.

The occurrence of failures not only affects the daily operation of ports but may also lead to logistical bottlenecks, thereby affecting the entire supply chain and causing negative economic impacts on businesses. Therefore, the development of an advanced predictive maintenance system is crucial to ensure the continuous and efficient operation of port equipment. This system needs to integrate the latest monitoring technology and data analysis tools to collect and analyze data from port machinery in real-time, such as temperature, vibration, current, and operating cycles.

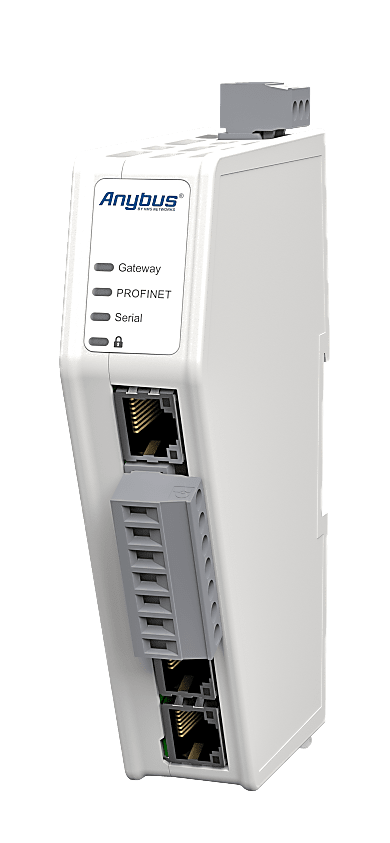

Within this system, stable protocol conversion gateways play a crucial role. These gateways effectively integrate port machinery with various communication protocols, ensuring smooth and accurate data transmission, and enhancing the reliability and security of the system. Faced with the challenges of harsh port environments and diverse equipment, protocol conversion gateways become a key link in connecting various devices, ensuring operational stability, and data security, which is indispensable for improving overall operational efficiency and equipment reliability.

Our client focuses on providing intelligent operation and maintenance solutions for large-scale machinery and industrial production lines, covering key industries such as port automation, new energy, mining, and rail transportation. In the field of port automation, their quay crane intelligent situation monitoring system is particularly outstanding and has become a leader in the industry. This system has not only gained recognition from leading enterprises in the industry such as Shanghai Zhenhua Heavy Industries ZPMC) but has also successfully entered the international market, widely used in dozens of countries worldwide.

In the quay crane intelligent situation monitoring system, various sensors monitor the operating status of port machinery in real-time, such as cranes, trolleys, front and rear beams, etc., and collect various status parameters such as vibration signals, speed signals, and temperature signals.

These parameters are collected into the data processing module (Online monitoring station), which is also the core part of the entire system, responsible for data processing, storage, and publication. The data processing module sends the collected and processed data to the port’s main control PLC system, which performs analysis, predictive maintenance, and early warning based on this critical data.

Since the data processing module only has a 485-communication interface, and the main control PLC systems vary greatly depending on the country and port users, how to use a reliable, stable, and high-performance communication gateway to transmit important data from the data processing module to the PLC has become an important issue in the quay crane situation monitoring system solution.

After comparing various options, the client adopted Anybus Communicator gateway to convert the data collected by the Online Monitoring Station into PROFIBUS or PROFINET and other protocols through serial conversion, enabling stable and reliable integration into different port main control PLC systems.maintenance, and early warning based on this critical data.

Numerous Anybus Communicator serial gateways have been deployed in the client’s quay crane intelligent situation monitoring systems in multiple ports worldwide, running stably and reliably. The simple and easy-to-use configuration features of Anybus Communicator serial gateway have improved the efficiency of user project implementation, gaining user trust. In subsequent port projects, Anybus gateway will be selected as a key communication component in their quay crane intelligent situation monitoring systems.

In the Anybus Product Emulator you can browse the Anybus Communicators intuitive user interface to get a look and feel of the configuration interface. It’s even possible to prepare configurations files without any product connected to your computer.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.